Brenham, Texas, [April 11, 2019] – The REM Research Group announces that the United States Patent and Trademark Office (USPTO) has issued a Notice of Allowance for U.S. Application Serial Number 14/354,843, a patent application directed at the benefits of REM’s ISF® Process on OEM Wind Turbine Gearboxes.

The patent claims ISF® Processed wind turbine gearboxes operate in full EHL lubrication regime, making possible the use of lower viscosity lubricants that do not require complex additive packages. This full EHL lubricant environment is ideal for wind turbine gearbox bearings, which are often considered the “weakest link” in the wind turbine gearbox. REM Surface Engineering proposes that if gears were superfinished, it would result in advantages such as a lower viscosity lubricant being used, producing a better operating condition for both the gears and the bearings. Lower viscosity lubricant allows finer filtration of damaging metal debris. A reduced lubricant additive package could be used and there would be no need to redesign the wind turbine gearbox.

The overall outcome will be wind turbine gearboxes that remain metal debris-free for many years, do not require lubricant or filter maintenance, and result in lower operating costs over a longer turbine life. This patent is a unique opportunity for REM Surface Engineering to advance Wind Turbine Technologies to the next level, where “filled for life” lubrication opportunities are being investigated. To this end, REM is seeking partners in the wind turbine industry to establish updated lubricant formulations to utilize this new technology.

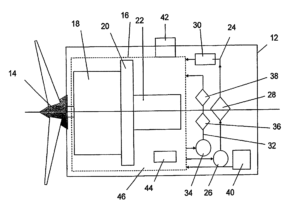

Wind Turbine Gearbox Lubrication System United States Patent Patent No . : US 10 , 233 , 905 B2

Wind Turbine Gearbox Lubrication System United States Patent Patent No . : US 10 , 233 , 905 B2

REM Surface Engineering, the inventor of the ISF® Process, the Rapid ISF® Process, the Extreme ISF® Process, and the REM® Process, is a global leader in providing surface engineering solutions. The REM’s isotropic superfinishing technologies are value-adding and performance-enhancing improvements to conventional machining operations such as grinding and lapping. Founded in 1965 in Southington, CT by Robert Michaud, REM Surface Engineering is a family-owned company that has proudly been serving our partners and customers for over 50 years. REM Surface Engineering operates four locations in Brenham, TX, Southington, CT, Merrillville, IN, and St. Neots, UK that provide products and services globally. For more information, please visit www.remchem.com.

Media Contact: Christina Michaud

cmichaud@remchem.com